RF & Microwave

RF components, microwave systems, and mixed-signal modules engineered for harsh environments.

RF components, microwave systems, and mixed-signal modules engineered for harsh environments.

To achieve success in an increasingly competitive electronic environment, advanced radar, electronic warfare and communication systems push the limits of what is possible for frequency, bandwidth, and SWaP. To meet these emerging challenges, industry must leverage the latest technologies in RF, microwave, and mixed-signal products.

By applying our proven expertise from digital, open-architecture boards to custom microwave solutions, we bring trusted, high-speed performance to mission-critical systems in space-constrained applications.

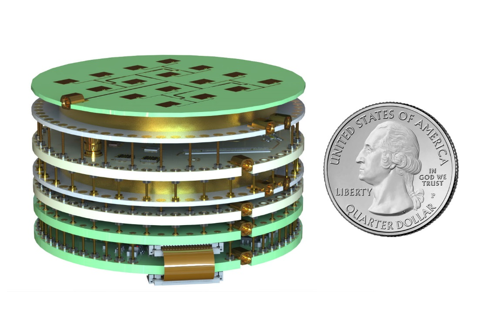

Versatile, highly integrated products for microwave up and down conversion

These purpose-built solutions deliver the latest in RF performance to harsh environments

Maximize system performance with low phase noise RF synthesizers and microwave signal generators

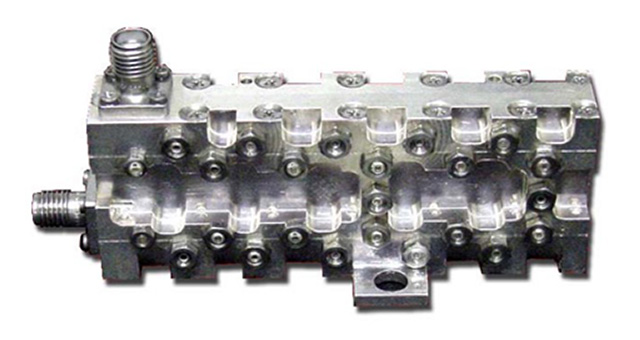

Broadband. High Power. Rugged. RF and microwave amplifiers for demanding applications

Our rugged active RF components include VCOs, mixers, limiters, switches, and noise sources

From space-qualified cavity filters to low-loss isolators, proven solutions for harsh environments

Over 40 years of experience developing space-qualified RF and microelectronic solutions

Speed your high-performance processing application with rugged COTS FPGA boards

Direct RF conversion with FPGA processing leveraging high-speed ADC, DAC and FPGA devices

Integrated Manufacturing

Utilizing the latest in automated RF manufacturing, we make production of cutting-edge technology scalable and repeatable, supporting your ramp to full-rate production while reducing risk. With 250,000 square feet of flexible manufacturing capability, we ensure delivery of high-volume high-quality product.

OPEN SYSTEM ARCHITECTURES

The pace of today's technology development means the traditional approach of custom-designed components, modules and subsystems is too slow. By adopting a modular open systems architecture approach (MOSA), we deliver the latest capabilities at the speed of relevance.